Why FRMC Hot Gas Filter Wins Other Bag Filters in Dust Removal

In recent years, with the rapid development of steel, new coal chemical industry, energy, non-ferrous metallurgy and other industries, a large amount of high-temperature flue gas has been generated in the production process. The flue gas contains a large number of dust particles, if directly discharged into the air, it will cause pollution to the environment. Filtering out the dust particles in the high-temperature flue gas has become a necessary measure taken for environment protection. As a result, hot gas filter emerges as the times require.

At present, most of hot gas filter elements on the market are made of organic fiber cloth bags with lightweight and low price. However, these bags have poor resistance to high temperature, and are easy to oxidize, easy to burn, and are difficult to clean up.

In addition to organic fiber materials, there are inorganic ceramic fibers, glass fibers and other fibers on the market. The emerging of inorganic materials overcomes the inherent defects of organic fibers and is more applicable to high-temperature flue gas dust removal. Ceramic fiber has excellent resistance to corrosion and high temperature. However, it tends to break easily when performing dust removal without machine shutdown. Meanwhile, glass fiber is difficult to bend and has a low wearing coefficient.

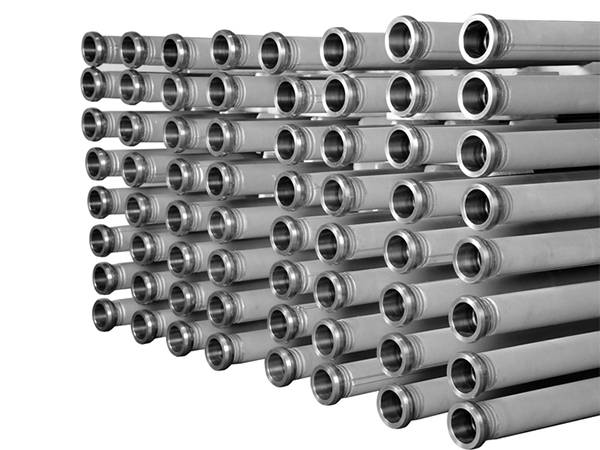

Made of FRMC (Fiber Reinforced Metallic Composite), our FRMC hot gas filter not only overcomes the disadvantages of organic fiber cloth bags, for example, poor resistance to high temperature and easy to corrode, but also overcomes the shortcomings of glass fiber and ceramic fiber, for instance, easy to fragile. Currently, our FRMC high-temperature dust removal filter elements have proven their advantages over other materials in many dust removal projects and have been highly praised by customers both at home and abroad.

- High temperature resistance. Up to 650 °C.

- Corrosion resistance. Made of FRMC, it is not easy to be oxidized and has good resistance to acids and bases.

- Non-flammable. Made of non-flammable metal materials, it will not spontaneously combust during operation.

- Easy to clean. Its surface is smooth and not easy to scale.

- High strength. Stable structure during reverse cleaning.

- Abrasion resistance. More than 24 months service life.

| Type | Standard FRMC Hot Gas Filter | Strengthened FRMC Hot Gas Filter | One-Piece FRMC Hot Gas Filter |

|---|---|---|---|

| Code | HGF-MFE | HGF-TWM | HGF-PSM |

| Features |

|

|

|

| Working Temperature | 450 °C | 450 °C to 650 °C | 450 °C to 650 °C |

| Specifications | O.D.: 130/155 mm Length: 2000/2500/4000/4500/5000/6000 mm |

O.D.: 60 mm Length: 1500/1750/2000/2250/2500/3000 mm |

O.D.: 60 mm Length: 1500/1750/2000/2250/2500/3000 mm |

| Connection Method | Flange end | Flange end | Flange end |

| Application | Coal-fired power, steel, metallurgy, cement industries, etc. | Non-ferrous metallurgy, chemical industry, energy, new coal chemical industries, etc. | Coal chemical industry, non-ferrous metallurgy, phosphorous chemical industries, etc. |

| Note: O.D. refers to the tube outer diameter. | |||

Filter installation accessories

Filter cartridge center distance dimension